PET preform mold manufacturing is a critical step in the production of PET bottles. The process involves creating a mold that will shape the plastic into the desired form of the bottle. In this article, we will take a closer look at the technicalities of PET preform mold manufacturing and understand the various stages involved in the process.

Design and Engineering:

The first stage of the PET preform mold manufacturing process is the design and engineering stage. This is where the design of the mold is created and the engineering specifications are developed. The design of the mold must take into account the specific requirements of the end product and the production process. This includes factors such as the size and shape of the bottle, the thickness of the plastic, and the type of closure that will be used.

CAD/CAM:

Once the design and engineering specifications have been developed, the next stage is the CAD/CAM stage. This is where the design is converted into a computer-aided design (CAD) file, which is then used to create the mold. The CAD file is used to create a computer-aided manufacturing (CAM) file, which is used to control the machinery that will be used to create the mold.

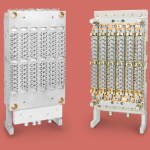

Mold Making:

The next stage is the mold making stage. This is where the mold is created using the CAD/CAM files. The mold is typically made from aluminum or steel and is created using CNC (computer numerical control) machines. The mold is then finished to the required specifications and is ready for the next stage, which is the trial molding stage.

Trial Molding:

During the trial molding stage, the mold is used to produce a small number of preforms. These preforms are then inspected to ensure that they meet the desired specifications. If the preforms meet the specifications, the mold is considered to be ready for production. If the preforms do not meet the specifications, the mold is modified and retested.

Production:

Once the trial molding stage is complete and the mold has been approved, it is ready for production. During the production stage, the mold is used to produce large quantities of preforms. The preforms are then cooled and inspected to ensure that they meet the desired specifications.

Maintenance and Repair:

PET preform molds are subject to wear and tear during the production process. Regular maintenance and repair are necessary to ensure that the molds continue to produce preforms that meet the desired specifications. This includes cleaning, lubricating, and replacing worn parts.

In conclusion, the technicalities of PET preform mold manufacturing are complex and require a high level of expertise. The process involves several stages, including design and engineering, CAD/CAM, mold making, trial molding, production, and maintenance and repair. Choosing a reputable and experienced PET preform mold manufacturer is essential to ensure that the molds produced meet the desired specifications and are of the highest quality.

At Acme Disys Systems Pvt. Ltd, we pride ourselves on being one of the leading PET preform mold manufacturers in the industry. Our team of experts has in-depth knowledge of the PET preform molding process and uses the latest technologies and equipment to produce molds that are accurate and consistent, ensuring that your end product meets the highest standards. We are dedicated to providing our clients with the best service and products, and we work closely with you to ensure that your specific needs are met. Contact us today to learn more about how we can help your business succeed in the PET preform molding industry.

Leave a Reply