For the success of your project if you are searching for a reputable plastic mold manufacturer and want to select an experienced and reliable partner then you can have a look. The best factors for this include production capacity, the manufacturer’s experience, quality standards, and customization capabilities. So with the above points and a more detailed overview, we can have a detailed discussion.

Understand Plastic Mold Manufacturing

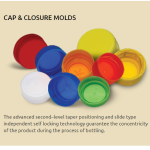

For producing a diverse range of plastic products across various industries this manufacturing method is widely utilized. This is created by engineers for appropriate specifications for molds which means this process begins with the design phase. Then comes the next step which is where molten plastic is injected into the mould cavity to take its shape as it cools and solidifies this process is the actual molding process. To ensure the final product meets the design specifications precision is the main thing in this place. The mold opens as the plastic solidifies and then comes the newly formed product.

In plastic mold manufacturing quality control is a very critical aspect and then comes the inspection that is used for identifying and then getting the defective parts.

Plastic Mold Manufacturing Process

Several key processes are used for the plastic mold manufacturing process. So here we’ll talk about all that.

Product Design

This process starts with the process of designing the plastic products that the molds will give. This includes 3D models using computer-aided design software that is designed to create designer specifications.

Mold Design

Engineers create the mold design depending on the product design. This includes selecting the material for the molds, determining the types of mold, and designing the mold cavity with the cooling system.

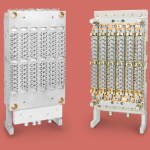

Mold Fabrication

Once the design of the mold is finalized then the mold will be fabricated. Then comes the techniques which are used to create the mold components with high accuracy such as CNC and other precession-made techniques.

Mold Assembling

Then we assembled the products like the core and cavity which are the individual components of the mold. Then comes the additional features that are been included by the mold like cooling channels, slides, and lifters.

Quality Control and Finishing

To ensure they meet the accurate and the best design molded parts undergo a quality control check process. This includes measurements and visual inspections. Some products may call for additional finishing processes like machining, trimming, and surface-related treatments to achieve the final desired product.

Quality Assurance and Testing

The integral part and most important part of manufacturing is quality assurance and testing. So under this, there are many integral points to be considered:

Design Verification and Material Inspection

This begins with the verification of the mold designs as well as the initial products. The material plastic used in the molding process is thoroughly examined for meeting specific standards such as composition and as well as strength.

Mold Inspection

Before undergoing the production process the inspection process is done which involves specific things to confirm its accuracy, design and completeness. Any issue in the product could result in defects in the final product.

Environmental Impact and Sustainability

To minimize the industry’s ecological footprint by addressing the environmental impact and promoting sustainability. Here are some points to be considered related to environmental impact and sustainability:

Material Selection

If you are opting and going for even recyclable and environmentally friendly materials. Recycled plastic can very well be used as they will lower their impact on the environment.

Energy Efficiency

Start implementing energy efficiency techniques in the process of manufacturing. This includes using products that will be using energy-efficient machinery and reducing energy consumption.

Conclusion

In various industries, plastic mold manufacturers play a very crucial role it provides the foundation for producing the wide range of plastic products that are becoming an integral part of our lives. So, in conclusion, the mold manufacturing industry embraces sustainability, and innovation to contribute to a more environmentally conscious and responsible future.

It can even solve all the issues related to the environmental impacts. The industry must continue to explore eco-friendly materials and manufacturing processes to reduce the environmental impact of plastic products.

Leave a Reply