In the world of manufacturing, particularly in the packaging industry, the quality and efficiency of production processes are paramount. A key player in achieving these goals is the Cap Mold Solutions Provider, a specialist in designing and manufacturing molds for caps used in a wide range of products, from beverages to pharmaceuticals.

What is a Cap Mold Solutions Provider

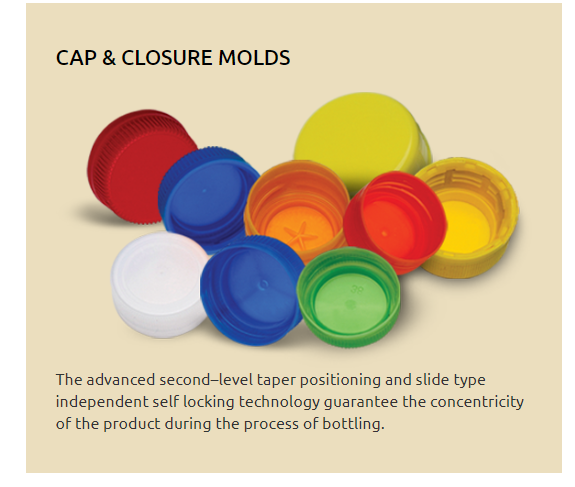

A Cap Mold Solutions Provider focuses on creating precision molds that are crucial for producing high-quality caps and closures. These molds are essential components in the injection molding process, where plastic or other materials are molded into the desired shape. The provider’s expertise lies in designing molds that meet the exact specifications of the cap, ensuring it fits perfectly and functions effectively.

The Importance of Cap Molds

Caps and closures may seem like minor components, but they play a critical role in protecting the contents of a container, ensuring product safety, and extending shelf life. Therefore, the accuracy and reliability of cap molds directly impact the overall quality of the product. A well-designed mold will produce caps with consistent dimensions, proper sealing properties, and durability, which are vital for maintaining the integrity of the product inside.

Key Services Offered by Cap Mold Solutions Providers

- Custom Mold Design: Providers work closely with clients to understand their specific requirements and design custom molds that meet precise dimensions and performance criteria. This includes accommodating various materials, sizes, and closure types.

- Rapid Prototyping: To ensure that the final mold design is perfect, providers often offer rapid prototyping services. This involves creating a prototype of the mold to test and refine the design before full-scale production begins.

- High-Quality Materials and Manufacturing: Cap molds are made from high-grade materials that withstand the rigors of the molding process. Providers ensure that their molds are manufactured with precision and durability in mind, using advanced techniques and equipment.

- Maintenance and Support: Ongoing maintenance and support are crucial for keeping molds in optimal condition. Cap mold solutions providers offer services to clean, repair, and refurbish molds, ensuring long-term reliability and performance.

Why Choose a Cap Mold Solutions Provider?

Choosing a specialized cap mold solutions provider offers several advantages:

- Expertise: Providers bring deep industry knowledge and technical expertise, ensuring that the molds meet the highest standards of quality and performance.

- Innovation: They stay at the forefront of technological advancements, incorporating the latest innovations in mold design and manufacturing.

- Efficiency: By optimizing the mold design and production process, providers help reduce production costs and time, leading to faster turnaround and improved overall efficiency.

Conclusion

In the competitive world of manufacturing and packaging, the role of a Cap Mold Solutions Provider is indispensable. Their expertise in designing and producing high-quality molds ensures that caps and closures are not only functional but also contribute to the overall success of the product. By partnering with a trusted provider, companies can achieve greater precision, efficiency, and reliability in their packaging solutions, ultimately leading to enhanced product quality and customer satisfaction.

FAQs: Cap Mold Solutions Provider

1. What is a Cap Mold Solutions Provider?

A Cap Mold Solutions Provider specializes in designing and manufacturing molds for caps and closures used in packaging. These molds are crucial for producing high-quality caps with precise dimensions and functional properties.

2. Why are cap molds important?

Cap molds are essential because they ensure the consistent production of caps that fit securely and function effectively. Properly designed molds contribute to the safety, integrity, and longevity of the product they seal.

3. What types of caps can be produced with these molds?

Cap molds can produce a wide variety of caps, including screw caps, snap-on caps, flip-top caps, and more. They are used in packaging for beverages, pharmaceuticals, cosmetics, and other products.

4. Can I get a custom mold designed for my specific needs?

Yes, Cap Mold Solutions Providers offer custom mold design services tailored to your specific requirements. They work with you to create molds that meet your exact specifications and production needs.

5. What is rapid prototyping, and how does it help?

Rapid prototyping is the process of creating a preliminary version of the mold to test and refine the design before full-scale production. This helps identify and resolve any issues early on, ensuring that the final mold performs optimally.

Leave a Reply