In the dynamic world of manufacturing the demand for precision and innovation is very essential, especially for companies focusing on PET preform and cap molds. In India, the die and mold industry is experiencing significant growth, driven by advancements in technology and increased demand across various sectors. As of 2024, India’s die and mold industry is valued at approximately $5 billion, with projections indicating it could reach $7 billion by 2028, reflecting a strong compound annual growth rate (CAGR) of 6.5%.

This growth is fueled by the rising demand for high-quality molds in the automotive, consumer goods, and packaging industries, where precision and durability are crucial.

In this blog, we will discuss the key role of die manufacturers in India, exploring how their advanced technologies and innovations are providing companies with a strategic advantage in the competitive global market.

Why Die Manufacturers in India Are Leading the Way

Die manufacturers in India are leading the way due to a combination of factors that position them at the forefront of the global industry. India’s die and mold sector benefits from a rich pool of skilled engineers and technicians, coupled with substantial investments in modern technology, which includes precise CNC machines and advanced 3D printing capabilities.

Indian manufacturers are known for their ability to deliver high-quality products at competitive prices, thanks to a strong supply chain and cost-effective production processes. This combination of technical expertise, innovation, and cost efficiency enables Indian die manufacturers to meet inflexible international standards and rapidly evolving market demands, making them key players in shaping the future of manufacturing on a global scale.

Advanced Technology Integration

Top die manufacturers in India are at the forefront of the industry by shifting towards advanced technology. Their investment in cutting-edge machinery and refined manufacturing processes make sure that dies, whether for PET preforms or caps, are produced with unmatched precision.

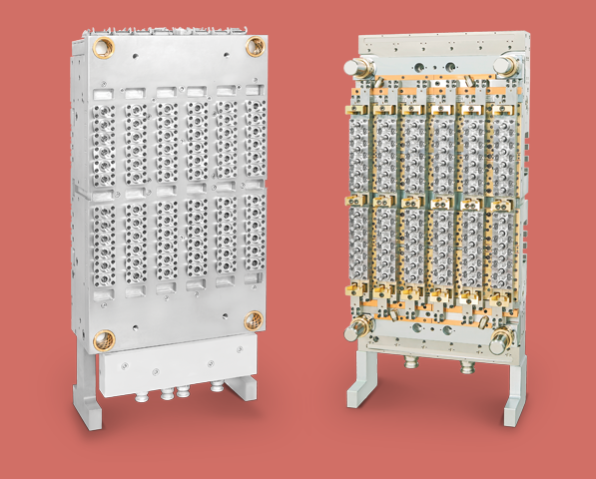

Expertise in PET Preform Molds

PET preform molds are important for industries such as beverage and packaging. Leading die manufacturers in India have sharpened their expertise in crafting molds that optimise the PET injection molding process. These molds are designed to improve production efficiency, minimise defects, and ensure the highest quality of preforms. The ability to produce precise and reliable PET preform molds is a testament to the advanced capabilities of Indian die manufacturers.

Precision in Cap Molds

Cap molds require to maintain exceptional accuracy consistency and functionality. The top die manufacturers in India specialise in creating high-quality cap molds that attach to tough industry standards. These precision-engineered molds are designed to produce uniform and reliable caps, which are crucial for maintaining product integrity and meeting regulatory requirements across various sectors.

Customised Mold Solutions

We need to understand that each production requirement is unique, leading die manufacturers in India offer customised mold solutions. By working closely with clients, these manufacturers develop customised molds tailored to fulfil specific needs. This customisation not only improves the efficiency of the manufacturing process but also helps in achieving precise specifications, contributing to overall production success.

Commitment to Quality Assurance

Quality assurance is crucial for top-notch die manufacturing. Leading Indian manufacturers follow strict quality control processes, providing every die whether for PET preforms or caps meets high standards through detailed testing. This focus on quality guarantees consistent performance and durability, minimising production issues and extending the life of the molds.

Comprehensive Customer Support

Die manufacturers offer more than just molds. They also provide complete support to their clients, including help with technical issues, maintenance, and after-sales service. This thorough support ensures that clients can keep their molds running smoothly and quickly solve any production problems that appear.

Emerging Trends in Die Manufacturing

The die and mold industry is evolving rapidly. Let’s discuss some key trends shaping its future:

Smart Manufacturing and Industry 4.0: Advanced technologies like IoT and automation are improving production efficiency, precision, and quality by enabling real-time monitoring and data-driven decision-making.

Advanced Materials and Processes: New materials and 3D printing are enhancing mold durability and allowing for complex, customised designs.

Sustainability: Die manufacturers are adopting eco-friendly practices to reduce waste, recycle materials, and minimise energy use, meeting both environmental and consumer demands.

Digital Twins and Simulation: Virtual replicas of molds (digital twins) help manufacturers test and optimise designs, reducing errors and speeding up production.

Enhanced Customisation: Modular and adaptable mold designs are becoming popular, allowing for quicker adjustments to meet specific production needs.

Increased R&D Investment: Ongoing research and development are driving innovation in mold technologies and processes, helping manufacturers stay competitive.

Why Acme Disys is a Premier Choice Among Die Manufacturers in India

Acme Disys stands out as a premier choice among die manufacturers in India due to its exceptional combination of advanced technology, skilled craftsmanship, and a strong focus on quality. With a reputation for delivering precision-engineered molds and customised solutions, Acme Disys consistently meets high industry standards and client expectations.

Acme Disys is a top choice among die manufacturers in India for several key reasons:

- Advanced Technology: Acme Disys utilises modern machinery and cutting-edge technology to produce highly precise and reliable molds.

- Skilled Expertise: The company boasts a team of highly skilled engineers and technicians who bring extensive experience and technical know-how to each project.

- Customisation: We offer tailored solutions to meet specific client needs, ensuring that molds are designed for optimal performance and efficiency.

- Strict Quality Control: Acme Disys sticks to strict quality standards and conducts thorough testing to make sure each mold meets high performance and durability requirements.

- Comprehensive Support: The company provides strong customer support, including technical assistance and after-sales service, to help clients maximise mold performance and address any challenges.

The Growing Influence of Indian Die Manufacturers

India’s die manufacturing sector, valued at $5 billion and growing at 6.5% annually, is gaining global recognition for its innovation and precision. Indian manufacturers excel with advanced technologies like IoT and 3D printing, cost-effective pricing, and a skilled workforce. These factors make them competitive against other global hubs.

Looking ahead, the industry is expected to continue expanding, reaching $7 billion by 2028. Future growth will be driven by further technological advancements, increased focus on sustainability, and a greater global presence. With ongoing investments in R&D and talent development, India is well-positioned to maintain its leading role in the global market.

Conclusion

For companies seeking top-quality PET preform and cap molds, Acme Disys stands out as a leading die manufacturer in India. Our advanced technology, expertise in mold production, commitment to quality, and customer-centric approach make us the most preferred choice for industries worldwide. Explore how Acme Disys can elevate your manufacturing processes and deliver the precision-engineered solutions you need.

Contact Acme Disys today to learn more about our mold solutions and experience the excellence that sets us apart as a top die manufacturer in India.

FAQS

Why Are Indian Die Manufacturers Highly Regarded?

Indian die manufacturers are known for their advanced technology, skilled workforce, and cost-effective production, which ensure high-quality and precise molds.

What Are Pet Preform Molds Used for?

PET preform molds are used to produce PET preforms for bottles and packaging, ensuring uniform quality and efficiency in the molding process.

How Can I Choose the Right Die Manufacturer?

Look for manufacturers with advanced technology, expertise in mold design, strong quality control, and good customer support.

What is the Benefit of Customised Molds?

Customised molds are designed to meet specific production needs, improving efficiency, and product quality, and reducing defects.

Why is Quality Assurance Important in Die Manufacturing?

Quality assurance ensures that molds are precise, durable, and reliable, reducing defects and extending their operational lifespan.

Leave a Reply